Dock Height

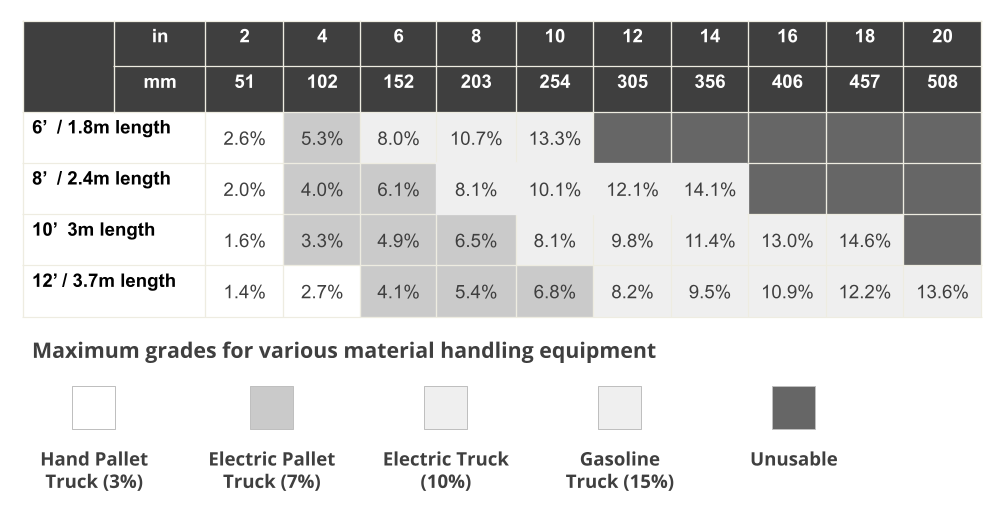

Dock height and truck bed height will determine the operating grade of the dock leveler. The general selection criteria is the maximum grade percentage from dock to vehicle: when using electric powered handling equipment it is 10%, and for gas or diesel powered equipment 15%. Exceeding these grade percentages may result in equipment "hang up", damage to handling equipment and load spillage.

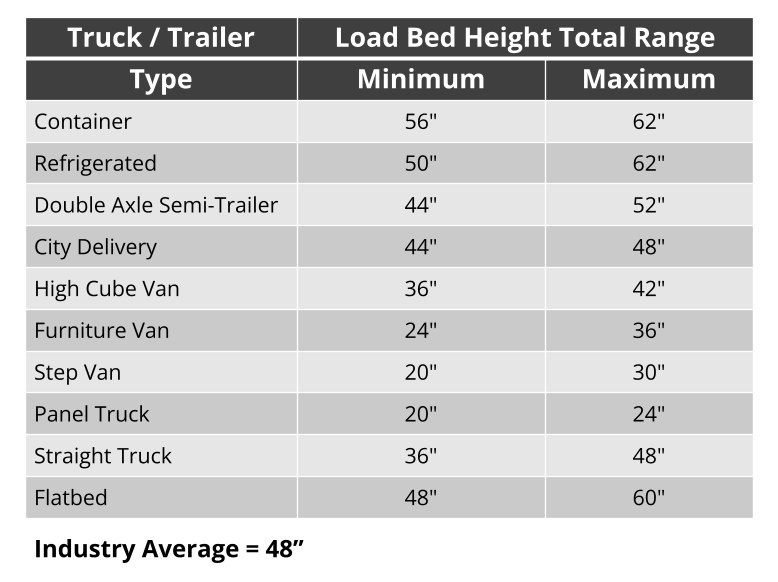

Vehicle beds range from 30" to 62" (762m to 1575mm) in height. The question is: what vehicles will be serviced at the facility with the greatest frequency? Once this is determined, all or a majority of the docks should be made to accommodate this bed height.

Dock And Vehicle Height Differential

A dock area should be flexible enough to accommodate any vehicle. The most common dock height is 48” – 52” (1219 to 1321mm).

Substantial height differences between dock and trailer can create severe dock leveler grades, decreasing the overall effectiveness of the operation.

Improper applications and use of dock levelers when there is a severe grade difference can lead to damage and premature failure of the dock levelers. Customized dock levelers can be made to suit unique applications and offset the height difference.

Dock levelers are available in several standard lengths of 6'-0", 8'-0", 10'-0" and 12'-0" lengths, depending on the specific model.

One of the most important considerations in dock leveler length selection, is the consideration of dock to truck bed height ranges and under clearance requirement of the material handling equipment used to load/unload material from the truck.

Added dock leveler length lowers the dock leveler grade in and out of the truck, increases dock safety, adds to dock leveler life, reduces potential for spillage/damage of materials and increases loading dock efficiency.