What Is the Difference Between a Mechanical & Hydraulic Dock Leveler?

A dock leveler acts as a structure to bridge the gap between the trailer bed and the facility floor. By bridging the gap, a dock leveler helps to improve the loading and unloading process and create a safe loading dock.

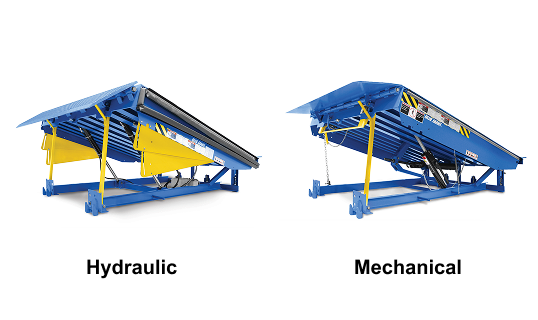

Picking the right dock leveler is a long-term investment and you want to make sure whatever dock leveler you choose will be safe, improve productivity, provide long-term service, manage heavy loads and maintain a smooth transition. Although there are many dock levelers available, hydraulic and mechanic are the most common types.

Hydraulic Dock Leveler

Hydraulic Dock levelers use electrical components in combination with hydraulic cylinders and pumps to lift the dock leveler and lip, deploying or storing the unit with ease. With the use of a control panel, the hydraulic dock leveler is engaged to the correct height and aligns with the trailer bed. As a result, hydraulic dock levelers are easier and more convenient to operate as they do not require the operator to do any manual work.

Mechanical Dock Leveler

Cost

Use

Maintenance

Can you Upgrade from Mechanical to Hydraulic?

If you already have a mechanical dock leveler and you’re not ready to pay for a new hydraulic dock leveler, consider a Hydraulic Conversion Kit. This kit will subsidize the springs and mechanical parts for the hydraulic operation of the deck and the lip.

When it comes to choosing a loading dock, there are a great deal of factors to consider: budget, amount of use, operator safety, maintenance and more. If you have more questions or need help making your final decision, we are here to help you find the right solution. Book a free consultation with one of our Blue Giant Sales Engineers and we can talk about your options.

Find the Right Dock Leveler for Your Operations

If you're unsure which dock leveler is right for your business, our team can help you assess your needs, explore options, and find the perfect solution.

Contact Us