Upgrading Safety & Efficiency

How a Pharmaceutical Facility Upgraded Its Vehicle Restraints with Blue Giant

The Company

A leading pharmaceutical facility in Mississauga, Ontario, needed a reliable solution to improve the safety and efficiency of its loading docks. With high-volume operations requiring seamless trailer restraint functionality, ensuring compliance with safety standards was a top priority.

The Problem

The facility’s existing vehicle restraints were worn, rusted, and no longer providing the level of safety required. These outdated restraints posed a potential risk to workers and cargo, increasing the likelihood of trailer movement during loading and unloading. The company needed a durable, high-performance solution that could seamlessly integrate with their existing dock infrastructure while minimizing downtime during installation.

.jpg)

The Solution

To address these challenges, Northern Dock Systems, an exclusive authorized Blue Giant dealer in the GTA, supplied and installed three Blue Giant StrongArm® HVR303 Electric Hook Trailer Restraints at key loading dock positions.

Step 1: Safe Removal of Old Restraints

The first phase of the project involved removing the facility’s aging vehicle restraints. The installation team worked closely with the customer to minimize operational disruptions. The old restraints were carefully detached, all hoses were disconnected and capped, and the removed equipment was properly disposed of off-site.

Step 2: Installing Blue Giant’s StrongArm® HVR303 Electric Hook Trailer Restraints

To ensure a smooth transition, Northern Dock Systems’ technicians retained and modified the existing support plates to fit the new restraints. After installing the StrongArm® HVR303 restraints, the plates were spray-painted to prevent corrosion and match the black finish of the new units.

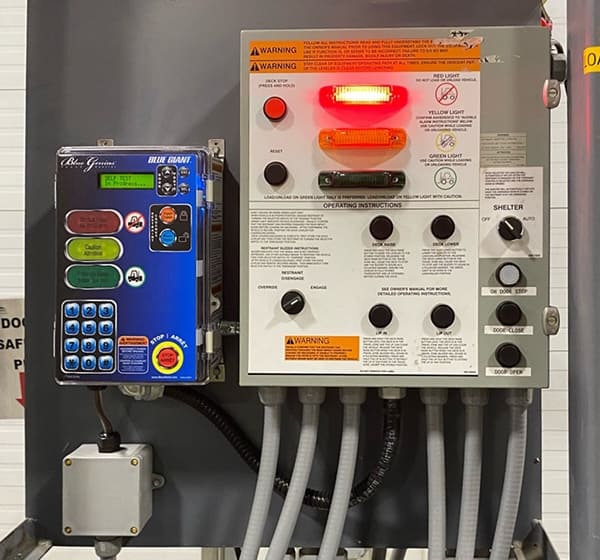

Step 3: Seamless Electrical Integration

The electrical team then connected the new restraints to Blue Genius® Gold Series II Control Panels using a 110V single-phase power supply. The control panels were interlocked with a relay to the facility’s existing dock panels for enhanced safety, and red/green traffic lights were installed outside for clear dock communication.

Step 4: Testing & Customer Approval

Once the installation was complete, the team conducted a full system test and provided a demonstration to the customer. The facility’s team was impressed with the improved functionality and reliability of the new restraints, and the project was signed off as a success.

Why the StrongArm® HVR303 Was the Right Choice

The Blue Giant StrongArm® HVR303 Electric Hook Trailer Restraint offers:

Enhanced Safety: Securely holds trailers in place, preventing dangerous movement during loading and unloading.

Instant Compensation Float: Adapts to a wide range of trailer heights, including those with damaged ICC bars.

High Restraining Force: Provides 32,000 lb (14,545 kg) of restraining power to prevent unexpected trailer movement.

Durability: Zinc-plated, heavy-duty motor resists rust and corrosion for long-lasting performance.

Weather Resistance: IP67-rated motor withstands extreme conditions and submersion up to 3.3’ (1m).

Eco-Friendly Design: A sustainable alternative to hydraulic systems, reducing carbon footprint and operational costs.

The Results

With the successful installation of Blue Giant’s StrongArm® HVR303 Electric Hook Trailer Restraints, this pharmaceutical facility now benefits from a safer and environmentally sustainable loading dock operation. The project highlights Blue Giant’s commitment to reliability and superior dock safety solutions.

.jpg)

.jpg)

.jpg)