Glossary of Loading Dock Terms

This section lists and defines terms (i.e. equipment and asset names, operating methods and conditions) used frequently in the loading dock industry.

Application Constraints: Characteristics of the application that could adversely affect the performance of a dock leveling device.

Authorized Person: Trained and/or qualified personnel approved or assigned to perform a specific duty or duties.

Capacity: The rating of the load that the manufacturer of the dock leveler deems to be appropriate for the design, based on the characteristics of the user’s application.

Complexity Factor: A factor typically determined by a set of characteristics that are present at the particular application.

Cracks: Material separations that are detectable to unaided natural vision

Cross-Docking: The process of moving cargo from the dock into or out of truck / trailer. The deployed dock leveler acts as a bridge for both pedestrian and forklift traffic.

Deck Beams: Longitudinal structural platform support beams.

Deck Plate: Top steel plate of the platform, covering the deck beams.

Dock Board / Dockboard: A plate-like structure with additional beam-like members located on two opposing sides of the plate and oriented parallel to the span of the plate, with members welded or bolted to the plate and have the dual purpose of providing additional support to allow the dockboard to support heavy loads such as from fork lift trucks, as well as providing a run-off guard, or curb.

Dock Bumpers: Pieces of molded or laminated rubber installed at the floor level of a loading bay to protect the wall from truck or trailer impact. Dock bumpers may also be steel-faced for added protection.

Dock Face: The outside wall of a loading bay.

Dock Leveler: A mechanical, hydraulic, or air-powered steel plate that can be raised and lowered to accommodate varying truck and trailer floor heights.

Dock Leveling Device: A device affixed to a dock structure, usually incorporating a mechanism to aid in positioning the device with respect to the bed (or loading surface) of a transport vehicle, thus creating a bridge for industrial vehicles between the transport vehicle and the dock structure.

Dock Lift: A hydraulically-operated platform mainly used to load or unload cargo from trucks and transfer it to dock or ground level.

Dock Plate / Dockplate: A plate-like structure designed to carry loads without the assistance of additional supporting members, and is typically used for lighter loads associated with foot traffic and hand trucks.

Dock Seal: A rubber or vinyl inflatable seal that extends from a dock face to close the gap between the loading dock and the truck / trailer entrance.

Dock Shelter: A rubber or vinyl shelter (may be rigid or retractable) that protects the space between the loading dock and the truck / trailer entrance from rain, snow, and debris entry.

Fixed Type: The dock lever is attached to the dock structure and usually incorporates a mechanism to help deploy and position the lip on the truck or trailer.

Fork Entry: The opening between a pallet's decks to admit forks.

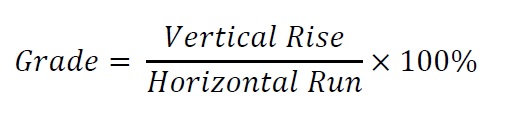

Grade: Percentage of slope, calculated using the equation:

Industrial Trucks: Wheeled vehicles (may be powered manually, electrically, or by gas or propane) used to pick up, transport and deposit single loads.

Lift Tables: Ergonomic devices used to raise, lower or tilt work loads such as boxes and pallets, enabling the worker to access the load at an acceptable level.

Lip: The extension member end of a dock leveling device that supports the leveling device on the transport vehicle bed and provides a transition to the transport vehicle bed. Lips are usually pivotally attached to the platform portion of the leveling device.

Loading Dock: The building area or structure where goods are moved to and from a transport vehicle. The dock is usually elevated above a driveway where the transport vehicle is parked.

Loading Dock Operating Personnel: A person or persons engaging in the process of loading and/or unloading transport vehicles whereby the activities could include the operation of industrial vehicles, dock levelers, vehicle restraints, dock doors, etc.

Loading Ramp: Synonym for dock leveler.

Manual Operation: Placement of a dock leveling device in its operating position by the manual effort of the dock attendant (i.e., without any powered or mechanical assistance).

Material Handling: The movement, storage, and protection of goods, materials, and products throughout the process of manufacturing, distribution, consumption and disposal.

Mechanical Operation: Placement of a dock leveling device in its operating position by other than manual or powered means (e.g., pulling a chain release allows leveler to pivot up using spring mechanism; then operator walks it down into position so that a ratchet and pawl mechanism can hold it in place).

Narrow Aisle Truck: An industrial truck that allows right angle stacking in aisles narrower than those normally required by counterbalanced trucks.

Operator: A person trained to control the movement of the dock leveler.

Operating Range: The maximum vertical range of travel above and below dock level.

Order Picker: An industrial truck designed so that the stand-up cab portion moves up and down along with the load, allowing the operator to pick items directly from the storage area.

Owner / User: Owner, lessee, person, or organization controlling the building or dock in which a dock leveling device is used.

Pallet Truck: A manually powered fork truck used to move and position pallets.

Platform: The main structural body of a dock leveling device.

Powered Operation: Placement of a dock leveling device in its operating position by hydraulic, pneumatic, electric or other externally supplied power.

Proper Use: When a dock leveling device is applied, installed, and used in accordance with the manufacturer’s recommended instructions and this standard.

Run-Off Guard: A vertical projection running parallel with normal traffic flow at each side extremity of the dock leveling device.

Toe Guard: A shield that is mounted to the side of a platform surface to provide toe protection when the dock leveling device is above dock level.

Transport Vehicle: A cargo-carrying vehicle (e.g. a truck, semi-trailer, trailer, or railcar) which may be entered upon by a powered or non-powered industrial truck to load or unload material.

Uncontrolled Drop: Sudden loss of support of a loaded platform.

Working Range: The recommended range of travel, above and below dock level, for which loading and unloading operations can take place, as defined in the information made available by the manufacturer of the dock leveling device.